1500Bar High Pressure 3D Water H3 Orbiter Blasting Tank Vessels cleaning machine tools

Shenzhen Panwin Machinery&Equipment Co.,Ltd. is well-established Water blasting &Cutting machine components manufacturer in China,We are leading supplier of efficient and high-quality Ultra-hi-pressure water-jet Parts to our worldwide customer for industrial cleaning&Cutting. Our High-pressure Water-jet components are manufactured high-quality with reasonable price, it is welcomed by our globally partner, we are looking forward to becoming mutual-benefit partner.

Send InquiryProduct Description

1500Bar High Pressure 3D Water H3 Orbiter Blasting Tank Vessels cleaning machine tools

1.Product Introduction of 1500Bar High Pressure 3D Water H3 Orbiter Blasting Tank Vessels cleaning machine tools

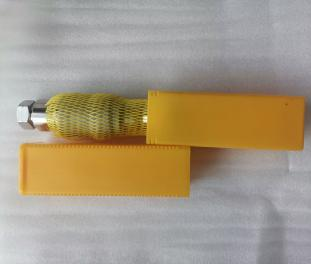

The 1500Bar High Pressure 3D Water H3 Orbiter Blasting Tank Vessels cleaning machine tools is designed to effectively and efficiently clean tanks and vessels. The rotation of the nozzles and body allow the tool to perform a complete 360 degree clean at pressures up to 22,000 psi (1500 bar).

Flow rates required are controlled through four different manifold options that provide 10 to 80 gpm (37 to 302 lpm): High Flow, Medium Flow, Low Flow, and Extra Low Flow.

A maintenance-free magnetic brake is used to control rotation speed.

2. Product Feature And Application of 1500Bar High Pressure 3D Water H-3 Orbiter Blasting Tank Vessels cleaning machine tools

This 1500Bar High Pressure 3D Water H-3 Orbiter Blasting Tank Vessels cleaning machine tools is designed for powerful tank cleaning process tools, and it has powerful features as follows:

1) Made from stainless steel

2) Enhanced components for longer life

3)Rotational speed controlled by a maintenance-free magnetic brake

4)Four manifolds offered for application precision: High (50 to 80 gpm), Medium (28 to 55 gpm), Low (16 to 30 gpm), and Extra Low Flow (10 to 18 gpm)

3. Product Details of 1500Bar High Pressure 3D Water H3 Orbiter Blasting Tank Vessels cleaning machine tools

The 1500Bar High Pressure 3D Water H3 Orbiter Blasting Tank Vessels cleaning machine tools has many unrivaled advantage characteristic,following are some of the advantages:

A: Wide range of accessories are available including cage centralizers and extensions. Only 1” or 2” extensions can be used when the H-3 Orbiter is installed in the centralizer.

B: For pipe cleaning, the 1500Bar High Pressure 3D Water H3 Orbiter Blasting Tank Vessels cleaning machine tools can be placed in a centralizer with an optional kick plate. When installed with the centralizer, the kick plate allows for self generated forward movement with each 180° rotation of the manifold.

4. Product Qualification of 1500Bar High Pressure 3D Water H3 Orbiter Blasting Tank Vessels cleaning machine tools

Shenzhen Panwin Machinery&Equipment Co.,Ltd are a professional manufacturer specializing Hydro Jet Blasting Cleaning&Cutting machine parts,We strictly controls the whole process of product production according to the quality standard ISO9001-2015 and passed the quality Certificate, Years of experience in the production and design of Ultra-high pressure accessories and machinery, not only We are winning the trust and long-term cooperation of customers, but also accumulated rich design experience and industry sensitivity for us. We have been expanding and innovate to satisfy the market and customers needs and practical applications.

5. Deliver,Shipping And Serving of 1500Bar High Pressure 3D Water H3 Orbiter Blasting Tank Vessels cleaning machine tools

For the package we will Pack with utmost Care and ensure security and protection of goods.

A: We used the wooden case and all our wooden case are Plywood case or Wooden case is finished the fumigation treatment under the shipping requirement.

B: Our spare parts are packed and covered some layers by the Waterproof,rust-proof and shock-Proof soft packing material, mainly the 3-5mm thickness foam film etc. We require our packing staff cover thick enough and wrap with the plastic film or adhesive tape tightly to ensure the packing can avoid almost any possible damage in the delivery process.

C: For the fragile,sensitive items, like Plunger, We have the solid plastic box cover some layer by the Waterproof,rust-proof and shock-Proof soft packing material, mainly the 3-5mm thickness foam film etc and wrap with adhesive Tape.

D: Every Wooden Case have the strong and firm feet about 7-10CM length, it is easy to forklift and transport goods.

6. FAQ

1) What terms of payment do you accept ?

For large quantity regular orders, 30% T/T advance 70% T/T before shipment; for special OEM orders, 30% T/T advance 70% T/T before shipment; for small quantity or sample order, 100% T/T in advance.

2) In the water Blasting cleaning process,What two factors is more important, pressure(bar) or Flow Volume(LMP)?

The two factors pressures and Flow Volume are both critically important for your optimized best cleaning performance and spray effect, the pressure will determine your spraying power, and the flows Volume take dirt and sediment etc away.

3) How important to keep the nozzles clean?

In the Water Hydro cleaning process, the blocked nozzle will not have good clean effect ,and the clogged nozzles also can increase the backward pressure on the power pump,and cause damage to the pump, so regular clean or even replace nozzles is important.

7. Company Introduction

Shenzhen Panwin Machinery&Equipment Co.,Ltd are a professional manufacturer specializing Hydro Jet Blasting Cleaning&Cutting machine parts,We strictly controls the whole process of product production according to the quality standard ISO9001-2015 and passed the quality Certificate, Years of experience in the production and design of Ultra-high pressure accessories and machinery, not only We are winning the trust and long-term cooperation of customers, but also accumulated rich design experience and industry sensitivity for us. We have been expanding and innovate to satisfy the market and customers needs and practical applications.